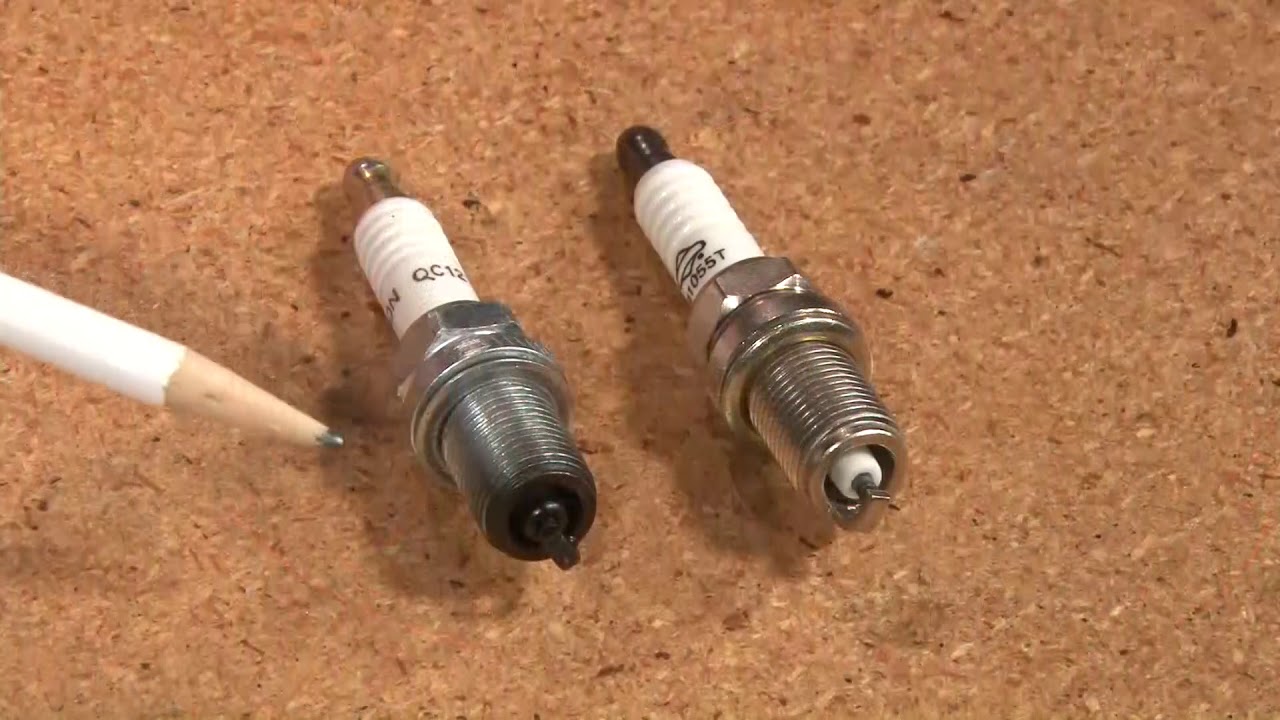

Remove the spark plug wire boot from the spark plug terminal.To test the engine’s spark plug and ignition coil: Both of these components can be tested with an ignition tester to determine if they’re functioning adequately or not. The ignition coil could also be malfunctioning. Because of this, it is recommended you replace the old spark plug with a new one at least once a year as part of your annual engine maintenance. The number one cause of ignition failure is a spark plug that has degraded due to carbon build-up and/or a weakened electrode.

#TESTING SPARK PLUG HOW TO#

How to test the ignition on a small engine This process continues with every revolution of the crankshaft until the engine is shut off. The momentum of the spinning flywheel provides enough force to push the piston back up where the spark plug will again ignite newly drawn in fuel and air.

This drives the piston back down through the cylinder to rotate the crankshaft. The spark plug fires and ignites the fuel and air mixture. On both four-cycle and two-cycle engines, fuel and air will enter the cylinder where it is compressed by the piston as it travels to the top of the cylinder. The magnetic field induces electricity, allowing the ignition coil to send voltage to the spark plug. The flywheel has permanent magnets built into it, and as it rotates past the ignition coil, a magnetic field is created. The rotating crankshaft connects to the piston which moves up-and-down within the cylinder and ignition process begins. When that start button is pressed, the ignition key turned, or the rope is pulled, the starter turns the flywheel which, in turn, rotates the crankshaft. Smaller four-cycle engines, and all two-cycle engines, rely on the operator to pull a starter rope to fire the engine up. The main difference between the two types of engines is that the four-cycle engine requires two revolutions of the crankshaft and piston to draw the fuel and air into the cylinder, ignite it, then exhaust the combustion gases the two-cycle engine requires just one revolution to do the same thing.Īdditionally, a larger four-cycle engine may utilize an electric start feature that allows the engine to be turned over by using an ignition key or a start button. Larger outdoor power equipment, such as lawn mowers, snowblowers, pressure washers, wood chippers, and more heavy-duty tillers will depend on four-cycle engines to provide the necessary torque, whereas smaller hand-held equipment, such as string trimmers, chainsaws, pole pruners, and leaf blowers, can get by with the lesser amount of torque provided by a two-cycle engine. Remind me about the difference between a two-cycle and a four-cycle engine? An ignition tester will speed up the troubleshooting process by allowing you to quickly determine if the spark plug or ignition coil is faulty on most two-cycle and four-cycle engines.

#TESTING SPARK PLUG PROFESSIONAL#

This can be done by using an ignition tester, a relatively inexpensive accessory that should be part of every tool box, whether you’re a professional landscaper or a do-it-yourself backyard enthusiast. One way to do this is to test the engine’s ignition system. To get your outdoor power equipment up and running as quickly as possible, you’re going to need to identify the source of the problem. The cause could be a defective spark plug, a malfunctioning ignition coil, a restricted carburetor, a clogged fuel filter, or something else entirely. Or, perhaps, you’re turning the ignition key on your lawn mower only to hear a brief straining whine before… silence. Even if the plug wires meet within their specifications, it doesn’t necessarily mean they are still in good condition as the insulation could be failing, terminals are corroded, or perhaps the conductor inside is broken and that would be show up if you were bending the wire while testing it creating and open circuit.You keep pulling the starter rope on your gas-powered string trimmer until it feels like you’ve dislocated your shoulder, but the engine won’t fire up. Touch the test probes together to determine the existing resistance in the test leads, then hold one test probe on one terminal, the other probe on the other terminal, this wire show’s 10,000 ohms, which by generic specs is good.

Setting the multimeter to the ohms sitting to measure resistance, on the 20k setting which will show us values in the 10,000 range. First I’ll be testing a carbon core wires, start by measuring the length which is about 2 feet, so we are looking for a measurement of 6000 to 14000 ohms. Keep in mind these are generic values and may vary between vehicle manufacturers and spark plug wire manufacturers. For copper core wires, the resistance will be 1 to 6500 ohms, inductive wires the resistance will be 2200 to 8000 ohms per 1 meter or 650 to 2500 ohms per foot and carbon wires, the resistance is 10000 to 23000 ohms per 1 meter or 3000 to 7000 ohms per foot.

0 kommentar(er)

0 kommentar(er)